SpinOlution is the evolution of the spinning wheel.

SpinOlution has evolved through feedback from the fiber community, incorporating real-world ideas from thousands of spinners to make spinning easier, faster, and more intuitive.

This page details that evolution: why changes were made and where the company is today.

Our History

-

Following the 2025 leadership transition, much of SpinOlution’s work happened quietly behind the scenes, focused on organization, clarity, and long-term stability. From streamlining the code used to cut wheel components to simplifying internal systems, the goal was to create consistency at every level of manufacturing.

At the same time, new dealership and affiliate-style opportunities were developed, allowing influencers and fiber artists to earn income simply by using and sharing their SpinOlution wheels on social media - expanding the brand through authentic, community-driven visibility.

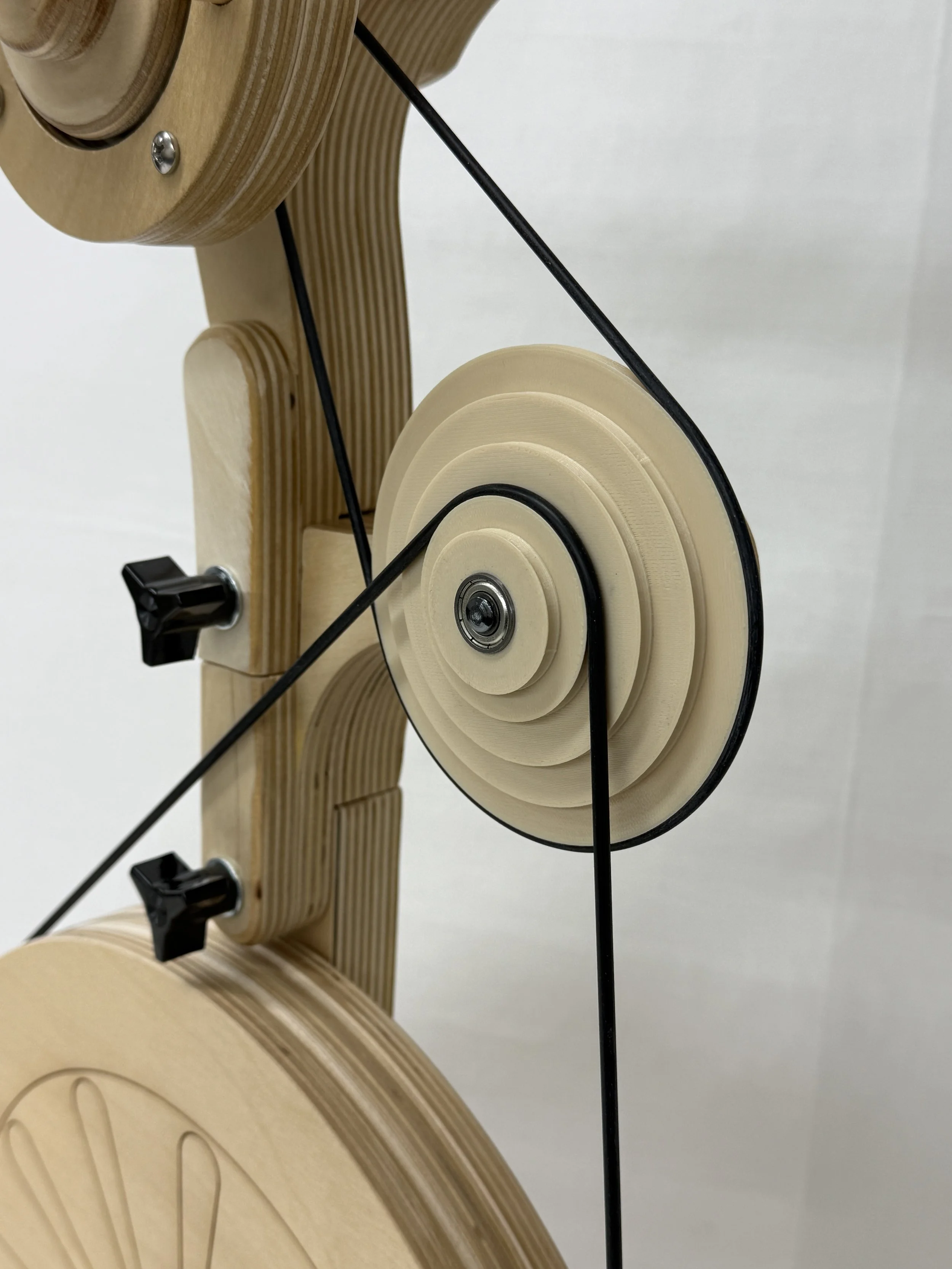

Design consistency and aesthetics also became a central focus. Birch-tone 3D-printed whorls replaced the earlier black versions to better harmonize with the natural wood of the wheels, while engraved wood hubs replaced black 3D-printed hubs on the Monarch and Echo, returning visual warmth and craftsmanship to these flagship models.

Engraving design options were expanded across the spinning wheel collection, allowing spinners to personalize their wheels while maintaining a cohesive, refined look.

This period also included thoughtful corrections to pricing and logistics. Package deals saw the largest price increase as they were recalculated to a flat 15% discount, while many individual spinning wheel prices were lowered to create more accessible, balanced, and competitive pricing across the line.

To address ongoing annual shipping increases, a $25 flat-rate shipping charge was introduced for SpinOlution wheel orders under $1,800 within the continental United States, with free shipping on wheel orders over $1,800. All accessory, parts, and furniture orders remain calculated based on size and destination for both domestic and international shipments.

Together, these changes reflect a broader commitment to clarity, cohesion, and rebuilding trust - ensuring that every SpinOlution wheel feels intentional, refined, and worthy of long-term investment.

-

In 2025, SpinOlution entered a defining new chapter with a leadership transition that prompted a comprehensive review of the company’s direction, manufacturing practices, and customer experience. One of the first major changes was the consolidation of manufacturing from Washington to California, bringing all production under one roof. This move allowed SpinOlution to establish tighter quality control, ensure consistent finishes across all wheels, and eliminate variations that had occurred when products were built in multiple facilities.

The transition also marked a deliberate return to wood-forward design, shaped by extensive customer feedback. While 3D printing had offered important advantages in domestic manufacturing and standardization, it had also led to aesthetic choices that did not resonate with all fiber artists. In response, SpinOlution began shifting away from visible 3D-printed components and back toward wood and wood-tone elements, balancing modern engineering with the traditional craftsmanship spinners value.

Equally important was a renewed focus on correction. Leadership acknowledged that some decisions made during the 3D-printing era had strained customer trust, and meaningful steps were taken to realign pricing, accessibility, and long-term sustainability. This period emphasized listening, refining, and stabilizing—moving away from constant evolution and toward a more consistent, dependable product line.

The 2025 transition ultimately set the foundation for SpinOlution’s current focus: fewer changes, better execution, and a renewed commitment to quality, clarity, and the trust of the spinning community.

-

As SpinOlution continued to evolve, the company entered a quieter but highly influential era centered on 3D printing.

With a strong commitment to being an American-made company, the goal during this period was to reduce reliance on overseas components and bring more production in-house. 3D printing allowed SpinOlution to manufacture critical parts domestically, including wheel hubs and tension blocks, while improving supply consistency and production control.

This era emphasized standardization and refinement, most notably through the move to uniform tension block sizing across models, improving consistency and ease of service. Whorls transitioned from aluminum (made overseas) to 3D-printed plastic, which also allowed SpinOlution to introduce lower ratios that balanced the extremely high ratios developed during the Golden Whorl period, giving spinners greater control across a wider range of yarn styles.

At the same time, this was a transitional season for the company. Founder Mike Pauly explored the future of 3D printing more deeply, ultimately launching SpinPerfect, and SpinOlution’s pace of visible change slowed.

While the functional benefits of 3D-printed components were clear, not all customers embraced the aesthetic shift - many longtime spinners preferred the traditional look and feel of wood. This era laid important groundwork for future refinement, clarity of direction, and a renewed focus on balancing performance, consistency, and craftsmanship.

-

Beginning in 2016 with the release of the Pollywog (a design concept by Ashley Martineau), SpinOlution entered a period focused on speed, refinement, and high-performance spinning.

The lineup continued to expand with the Worker Bee in 2017 and renaming the MACH III to the Monarch in 2018, reflecting a clear goal: to increase spinning speeds across the entire product line and create the fastest flyers on the market to date, particularly for spinning very short staple length fibers.

As performance demands increased, SpinOlution made a key engineering shift by increasing flyer shaft diameter from 1/4" to 3/8", reducing vibration and ensuring stability at higher speeds. The MACH III was retired in 2018, and by 2019 the Hopper was upgraded to the Golden Whorl system, bringing legacy models into this new performance standard.

Golden Whorl models built upon all Wooden and Corian Whorl engineering while introducing major performance upgrades, including:

Higher ratio speed options

Reduced flyer drag

Improved silenced bearings

Knockless treadle on the Echo and Monarch

Significantly enhanced overall performance.

This era cemented SpinOlution’s reputation for speed, control, and innovation at the highest levels of spinning.

-

In 2013, SpinOlution entered a new phase of refinement and performance with the introduction of the King Bee and the first Firefly, expanding the lineup to include more modular designs and innovative electric spinning options.

This era reflected a shift toward improved materials and user-focused enhancements while building on the strong engineering foundation established in earlier models.

By 2015, as newer technologies and designs took center stage, the MACH II and WIND models were retired, making room for a more streamlined and forward-looking product line.

Corian Whorl models retained all of the proven Wooden Whorl engineering features while introducing key design advancements, including

Magnetic bobbins and magnetic orifice bars for easier use

Corian whorl material for durability and consistency

Improved nylon flyer pegs

Modular head designs

Overall performance enhancements (better bearings, more ratios).

This period marked an important step in SpinOlution’s evolution toward smoother operation, greater versatility, and more efficient spinning.

-

SpinOlution’s story began in 2008 with the sale of the first MACH I, marking the start of a new approach to spinning wheel design rooted in engineering, innovation, and real-world spinner feedback.

In 2009, the line expanded rapidly with the introduction of the Bee, Echo, and MACH II, establishing SpinOlution’s commitment to offering wheels for a wide range of spinning styles and skill levels.

By 2010, SpinOlution continued to refine and grow its lineup with the launch of the Hopper and MACH III, while the original BEE evolved into the Queen Bee, reflecting a clearer vision for purpose-driven wheel design. That same year, the MACH I was retired, signaling SpinOlution’s willingness to improve, iterate, and move forward. In 2011, the release of the Wind (a bobbin-led version of the MACH II) further expanded the brand’s innovative footprint during this formative era.

All Wooden Whorl Spinning Wheels from this period featured what became hallmarks of SpinOlution engineering:

Warp-resistant, sustainably sourced heavy duty Baltic birch construction.

Easy-to-remove bobbins and intuitive tension adjustment.

Removable orifice bars with open hook orifices.

Ergonomic pendulum treadles

Open flyer pegs (in wood)

A comprehensive range of ratios capable of spinning everything from superfine to bulky yarns.

These early designs laid the foundation for the evolution of SpinOlution wheels and the spinner-focused innovations that continue today.

Our Process

Listen.

Every improvement begins with direct feedback from fiber artists, dealers, and instructors who use SpinOlution wheels in real-world conditions. Pain points, workflow interruptions, aesthetic preferences, and performance needs are carefully observed and documented before any change is considered.

Engineer.

Design changes are evaluated through the lens of spinning efficiency and wheel function: making yarn easier, faster, smoother, and more intuitive to create. This step focuses on performance gains, ergonomic improvements, reduced vibration, better ratios, and fewer interruptions to creative flow.

Refine.

New materials, components, or designs are tested in production and adjusted for consistency, durability, and manufacturability.

Once a solution proves effective, it is standardized across models to reduce variation, simplify maintenance, and improve long-term reliability.

Standardize.

Final decisions are measured against SpinOlution’s core values: craftsmanship, function, and customer trust.

If a change improves function but detracts from the spinner’s emotional or aesthetic connection to the wheel, it is refined or reconsidered - ensuring that innovation supports both performance and the timeless experience of spinning.

Let’s Work Together

SpinOlution has always grown through the ideas and feedback of the fiber artist community, and we welcome thoughtful input on how our wheels can continue to improve.

If you have suggestions, insights from your own spinning experience, or ideas that could make spinning easier, smoother, or more enjoyable, we invite you to share them - your feedback helps guide refinement, future decisions, and the ongoing evolution of SpinOlution wheels.