Routine Maintenance

SpinOlution Wheels have completely enclosed high performance bearings and never need oil.

Replace the tension block felt if your wheel starts to sing, squeal, or chirp.

Remove drive band when stored for prolonged periods.

Check for and tighten loose screws as necessary.

Check for and dust the wheel with furniture polish when necessary.

Maintenance Videos

We are grateful for the growing collection of educational videos created through the shared efforts of our help desk team, dealer network, and customers. These videos reflect the strength of the SpinOlution community and the willingness of experienced spinners to share their knowledge and time to help others succeed. Together, this library provides practical guidance, encouragement, and ongoing support for spinners at every stage, and we deeply appreciate everyone who has contributed to making these resources available.

About your SpinOlution Wheel

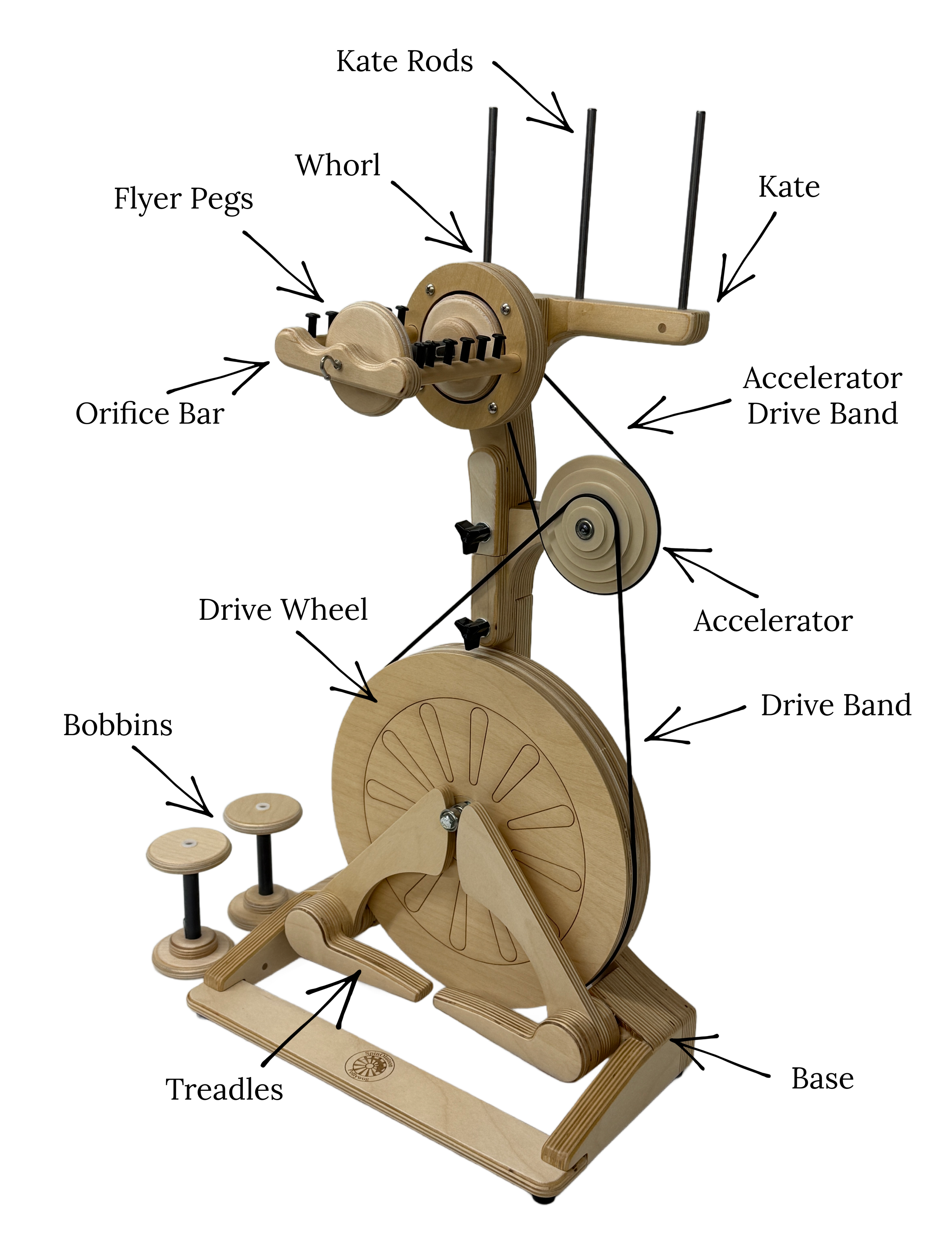

Treadling powers the drive wheel, which turns the flyer. If the wheel or flyer isn’t moving, check that the drive band is properly positioned in a ratio groove on the flyer whorl, not resting behind it. At lower ratios, treadling requires minimal effort, and you may even be able to spin using just one foot. As the ratio increases, more effort is needed, but SpinOlution wheels still require significantly less effort than other wheels. To stop the wheel, simply press both treadles gently, which halts the drive wheel and flyer.

The drive wheel turns when you treadle and helps determine your spinning ratio. On the Monarch, Echo, Bullfrog, and Pollywog, the drive wheel is the large wheel below the flyer. On the Hopper, the drive wheel is located at the back of the head and is driven by the thick drive band. On the Bee, the lower left wheel is the drive wheel, while the lower right wheel is the flywheel. The Firefly model does not have a drive wheel, as it is powered by a motor.

The accelerator, powered by the drive wheel, offers a wider ratio range and faster speeds for spinning fine yarns or short-staple fibers. SpinOlution wheels either come with an accelerator built-in or as an upgrade/accessory. For the Monarch, Echo, and Firefly, the 4 oz Accelerated (4A) accessory is great for spinning short-staple fibers like cotton. The Pollywog requires an accelerator accessory to be attached between the drive wheel and head, working with both 4 oz and 12 oz setups for 10 additional faster ratios. The Hopper has a built-in accelerator on the back of the head, providing a higher range of ratios and speeds. On the Bee, the left wheel is the drive wheel, and the right wheel is an accelerated flywheel.

Flyer bars have two wooden bars with black nylon pegs. The bars are "key-cut" with a flat top to fit into the orifice bar. Older models have round-topped flyer bars, which can be replaced with new, flat-keyed bars. Magnets on the flyer bars secure the orifice bar.

Flyer pegs are black nylon and offset to fill the bobbin evenly, guiding the yarn without snagging. They are easy to replace; simply unscrew and screw in new ones. You can customize peg height (e.g., 4 oz pegs are ½" tall, 8 oz pegs are 1", 16 oz pegs are 1", and 32 oz pegs are 2"). Order new pegs by contacting hello@spinolution.com

The flyer rod is where the bobbin slides on, secured by a magnet. Measure the rod’s diameter (¼" or ⅜") before ordering accessories. Orifice bars fit either size and come standard as a bypassable hook bar, which easily snaps on and off the flyer rod for bobbin changes.

Bobbins are available for ¼” or ⅜” flyer rods—measure your rod diameter before ordering. Each Flyer Head includes one bobbin, sized based on the amount of worsted weight medium wool it can hold, though this varies with fiber type. For example, one spinner fit 8 oz of silk on a 4 oz bobbin, and bulky yarns, like 16 oz of tailspun, fill a 32 oz bobbin quickly. SpinOlution bobbins feature leader clips for easy thread addition. Cut a 3-foot length of thread (cotton crochet thread is ideal for beginners), tie it in a loop, and place the knot under a clip. Lead from the front or back clip, bring the loop around the left pegs for spinning or right pegs for plying, and through the orifice.

Our stretchy drive bands are easy to swap between ratio whorls. It’s normal for them to leave black residue, which can be wiped off with a damp cloth. Keep the band out of direct sunlight to prevent brittleness, and always have a backup on hand. Drive bands are not covered by warranty.

Clockwise rotation of the tension knob increases tension, while counterclockwise decreases it. Use partial rotations for fine-tuning. The brake knob screws onto a threaded rod, pushing a spring, nylon bushing, and wooden block, which presses against a felt piece on the curved edge inside the head. This felt pushes on the bobbin rod. Tension blocks are reversible—if your wheel squeals, rotate the block to silence it before replacing the felt. Different spinners require different tension levels: fine yarn spinners may remove the block and cross-lace the flyer, while those spinning chunky or art yarns need more tension.

Recommended:

Extra drive band

Superglue

Extra tension block felt

A small Philips head screwdriver

An allen wrench set